1.Company Introduction

Fancy Diamond Co., Ltd., formerly known as Luoyang Qiming Superhard Material Co., Ltd., is a modern enterprise integrating R&D, production and sales of superhard material production equipment and its products.

Our production base is located in Luoxin Industrial Cluster of Luoyang City, covering an area of about 100000㎡. It has a complete set of mechanical processing, heat treatment, assembly and commissioning production lines and the large-scale intelligent synthesis workshop. The company has an annual production capacity of 500 Sets large-scale intelligent HPHT cubic presses. And it has a large-scale HPHT diamond production workshop and complete synthesis technology. Fancy Diamond is the largest HPHT cubic press production base in the world.

The HPHT cubic press of Fancy Diamond has a number of patented inventions, and has passed the ISO9001 quality system and CE EU certification. At the same time, Fancy Diamond has a mature foreign trade team and many years of foreign trade export experience. Now our equipment has been exported to more than 20 countries such as the United States, India, UK, Russia, Germany, Spain, Japan, South Korea etc., and we have reached long-term cooperation with many Fortune 500 companies. Together with our partners, we have successfully grown the largest single lab grown diamond by weight (150.8 carats) in the world using our equipment.

2.“Turn-Key”Project

Turn-key project is a brand-new concept proposed by Fancy Diamond to serve customers in an all-round way, providing customers with technical support in the whole process from project approval to full-scale production.

The purpose of the Turn-key project is to provide technical support for our partners who have in-depth cooperation intentions or have sufficient financial strength.

Technical support includes but is not limited to:

a.Equipmentmatching/ equipment installation/ equipment maintenance/ equipment operation training.

b.Single crystal diamond synthesis/industrial diamond production, etc.

2.1.Make equipment configuration recommendations according to the application direction of customer equipment

When using the same model of Fancy diamond HPHT cubic press to produce different superhard materials,the main difference lies in the difference between the hydraulic system and the electric control system.

2.2.1 Different types of hydraulic system configuration

a. Booster overpressure.

This type is a traditional overpressure method, which has the advantages of low noise, low failure rate and super stability, but the disadvantage is that the system occupies a large area and the one-time investment cost is high .

b. Super-high pressure pump overpressure.

The advantage is that the type is simple in structure and suitable for various process forms. It is the most widely used and stable hydraulic configuration on the market.

c.Reciprocating booster overpressure

The advantages of this type are low noise, small size, easy installation, and suitable for various process forms. The disadvantage is that the service life is unstable and has not passed the batch verification in the market.

2.2.2 Electronic control system

The electric control system consists of an industrial computer, a system classification controller, and the peripheral solenoid valve drive board, electrical components, sensors for grading current and voltage, and heating transformers to form an electrical control system of the press.

The system is composed of:

a.Host machine: Industrial computer, press controller, 19 inch LCD display, DI/DO Isolation Drive Board; cylinder head switching board, power control board, signal integration switching board, insulation testing board;

b.Sensor: Primary current sensor (range: 0~100 or 120A), Secondary Current Transformer (range: 2000A~6000A), Secondary Voltage Sensor (range: 0~10V), Pressure Transmitter (range: 0~100 or 150MPa);

c.Button Hand operatored buttons: Single Cylinder Forward Buttons (Six buttons), Forward Button, COMP(or Synthesis, they are same function ) Button, Return Button and Stop Button; Interface Buttons: Auto/Manual Button (A/M), Manual Pressure Relief Button, Quick Return Stoke Button, Emergency;

d.Output controller: 24-Channel Output(relay), 2-Channel D/A Output:: 0~5V or 0~10V.

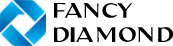

In addition, customers can put forward additional requirements for configuration according to specific product production needs(voltage can be customized). The specific parameters of the system are as follows:

2.2.Technical support for equipment use

In the process of cooperation with customers, Fancy Diamond is mainly responsible for the following technical support,

a.If the equipment fails, it is responsible for formulating a solution, and if necessary, Fancy Diamond should send professionals to the scene to deal with it.

b.Responsible for the production or purchaseof all equipment-related accessoriessuch as anvils, steel rings, big and small blocks, sealsetc.

c.If the customer needs, we can provide synthetic cubes or carry out related technical cooperation.

If the customer needs, we can provideother auxiliary equipment, such as oven, hydraulic press, post-processing equipment, UPS, etc.

2.3.Equipment installation and debugging

Fancy Diamond has an experienced equipment assembly and commissioning team, which can meet all the needs of customers for on-site installation and commissioning. The specific work content are:

a. Install the equipment

b. Debug the equipment

c. Guide product synthesis

d. Customer operation staff training

e. After-sales service

2.4.Help customers with equipment layout design and site and supporting project design

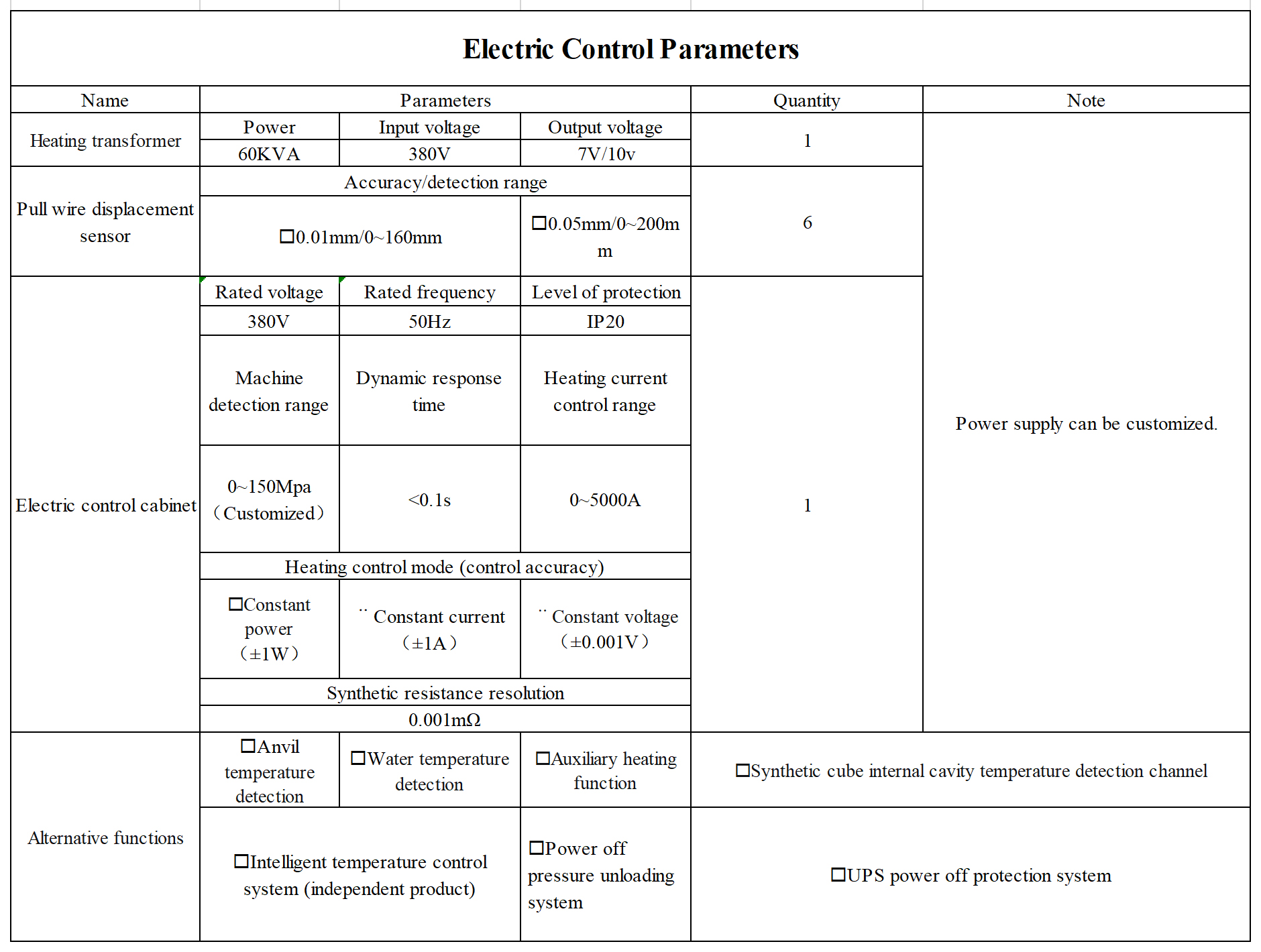

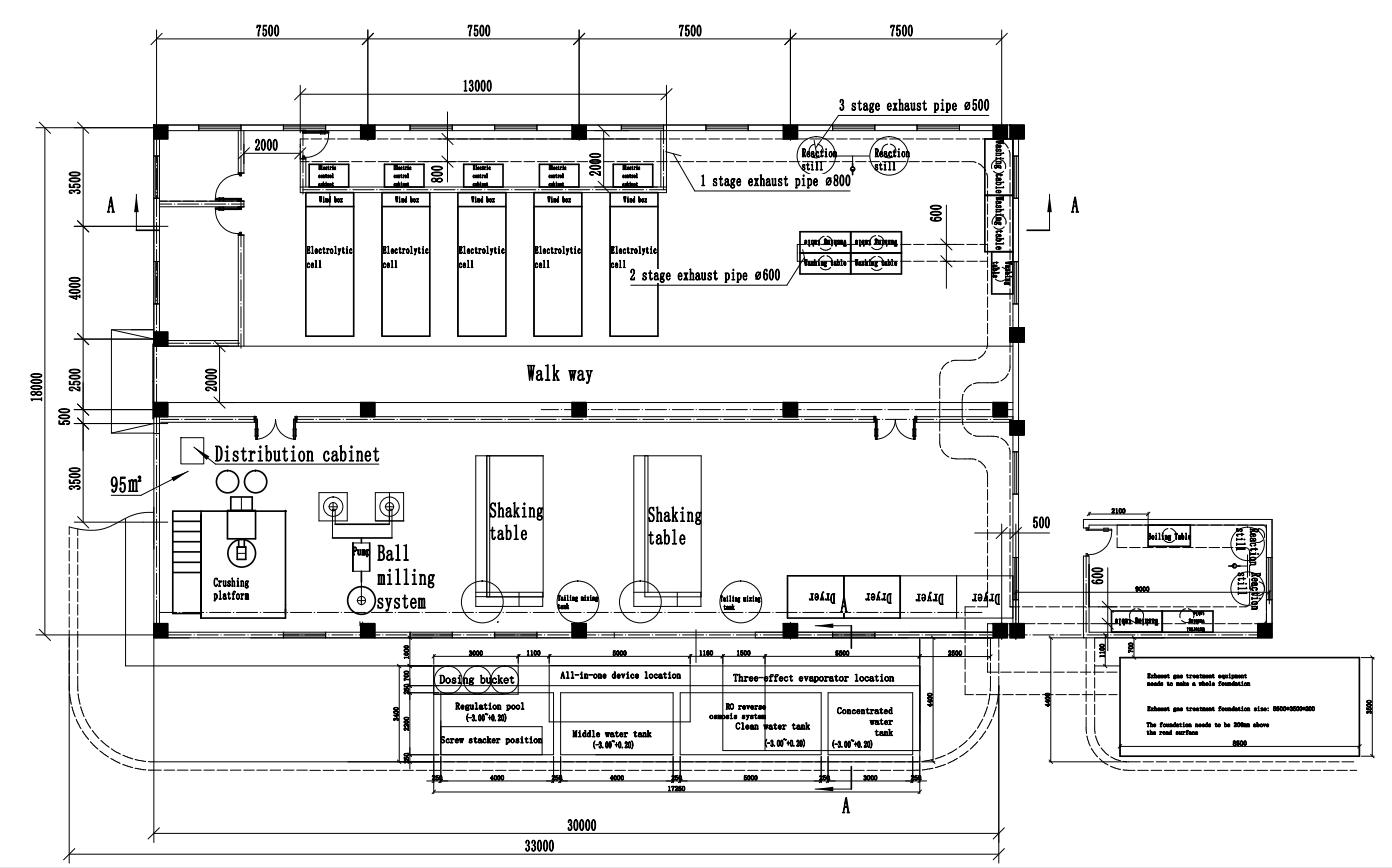

According to the model of the HPHT cubic press selected by the customer, it is an important part of our Turn-key project to carry out layout design and supporting project design for the customer. The following is based on the project of 50 sets QMYG850 cubic presses.

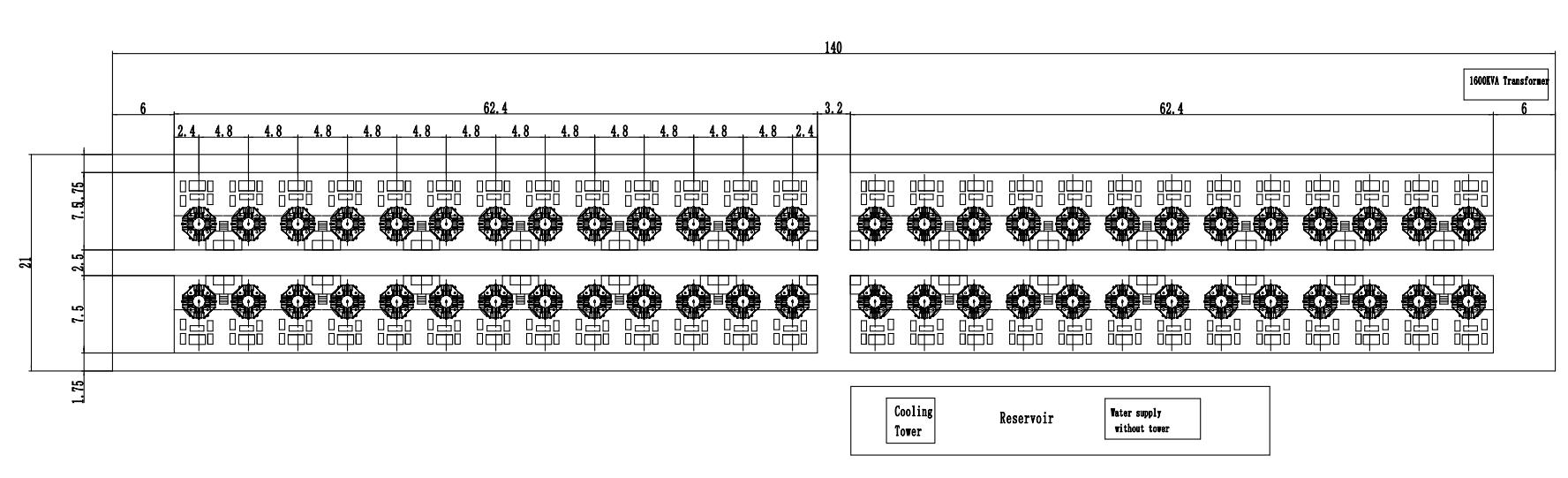

According to the actual demand, if the customer conducts industrial diamond production, customer needs to have a synthetic site and a post-processing site. The synthesissite is a standard factory building with a height of21m×140m and a lifting height of more than 8m. The factory building has two lifting equipment with specifications above 16 tons. A set of cooling circulating water system, and the workshop foundation should also be constructed according to the standard, a pickling site of about 45 ㎡ should be built, with a lifting device of more than 5 tons.If customers have requirements for environmental protection, an air and water treatment system should be added. The electricity requirement is to have a transformer with a power of more than 1600KVA.

Figure 1 Layout of QMYG850(50 sets) HPHT cubic presses

Figure 2QMYG850 base diagram

Figure 3Layout of post-processing and exhaust gas treatment equipment

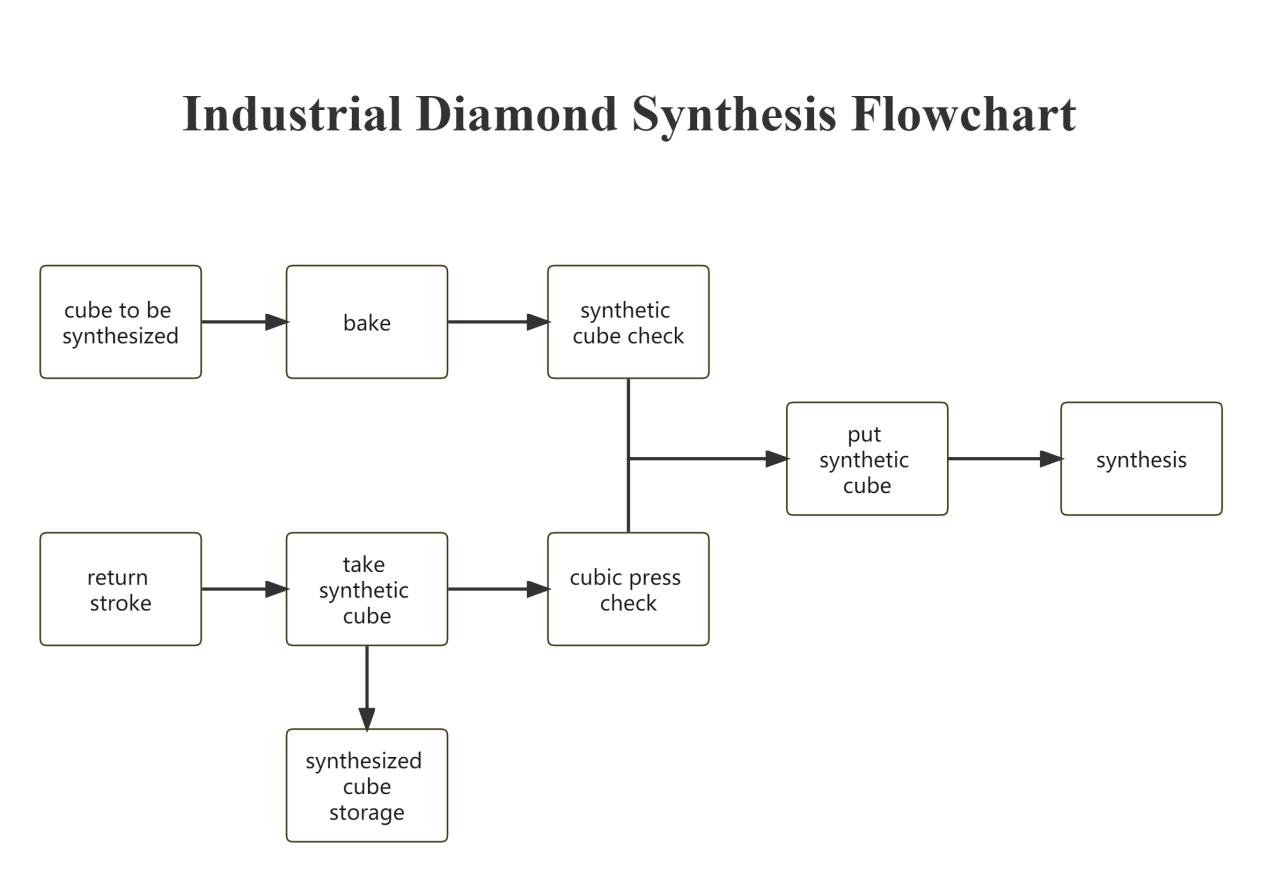

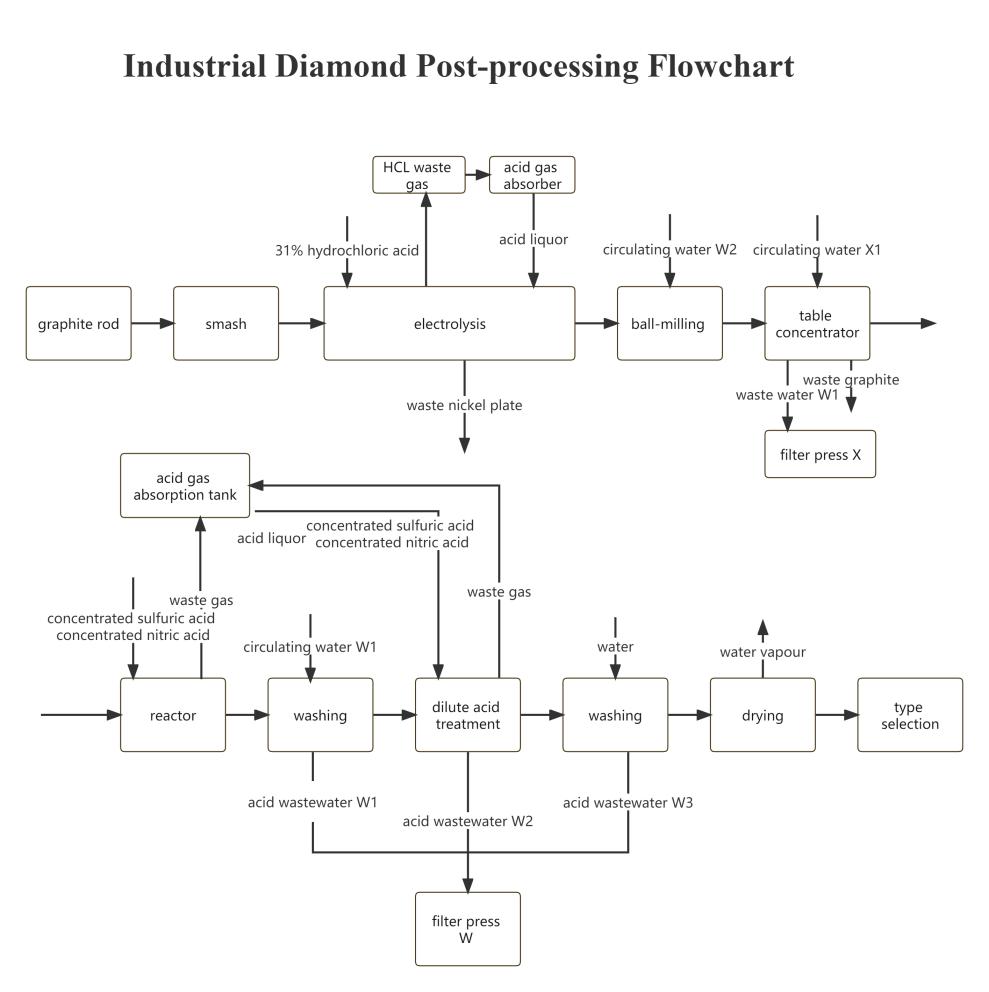

The flow chart of industrial diamond synthesisand post-processingis as follows

2.5.Recommendation of equipment model according to the application direction of customer requirement

At present, the press models produced by the Fancy Diamond are mainly QMWG650—QMWG1000 and QMYG650—QMYG1000,various models can meet the production and research of superhard materials such as industrial diamond,single crystaldiamond, cubic boron nitride(CBN) and composite sheet(PDC, PCD, PCBN). Please refer to the parameters of various models of cubic presses have been listed one by one in the companys Product Operation Manual. At present, the QMYG850 press produced by our company is the main model in the market for producing superhard materials such as industrial diamond and single crystaldiamond. It has been extensively verified in various fields in the market. It has safe, stable, easy to operate and maintain , higher cost performance and other advantages.

3.COI and ROI of equipment according to market conditions

Due to the different regions of the customers, some projects cannot be budgeted, such as workshop construction and infrastructure construction, electrical equipment addition, circulating water infrastructure and supporting related equipment, and post-treatment equipment purchase, etc. Therefore, this paper can only provide layout design and related equipment details (as shown in the figure above), configuration cost accounting is not performed. In addition, if customers need to import wastewater and waste gas treatment equipment from our company, cost accounting can be performed later.

3.1.ROI analysis

According to the standard configuration analysis, if the project scale is 50 sets QMYG850 HPHT Cubic Press, the equipment investment cost is 96.64 million USD.

If the project is applied to industrial diamond production, the single synthesis cycle of a single equipmentis 35 minutes, the single synthesis output is about 450 carats, and the annual output (calculated according to the frequency of start-up time is 0.98) is about 6,622,560 carats; the average market price of industrial diamonds. The cost per carat is about 0.29 USD, and the cost per carat is about 0.15 USD, so the gross profit per carat is about 0.14 USD. Through the above statistics, the annual output and sales revenue of 50 presses is 96 million USD, and the gross profit is 46 million USD.

Single equipment gross profit analysis table Unit: USD | ||

Items | Amount | Note |

Ⅰ Operating income | 8,025,750.00 | |

Ⅱ Operating cost | 4,710,360,46 | |

synthetic cube, preheating cube, etc. | 3,894,260.46 | |

consumable materials | 20,000.00 | · Acid lotion, industrial salt, gloves. |

depreciation (50 sets) | 713,100.00 | The unit price is 1,933,800 USD including tax, and the monthly depreciation amount of 50 units is 713,100 USD |

post-processing and environmental protection equipment | 25,000.00 | Wastewater treatment facilities, water circulation devices, etc., are depreciated on a 10-year basis. |

staff salary | 58,000.00 | 51 synthesis workers, 4 washing workers, 2 selection workers, 1 supervisory engineering staff |

Ⅲ Gross profit | 3,315,389,54 | |

Ⅳ Gross profit margin | 41.31% | |

Single equipment synthetic cube consumption | |||

Specification | Qty./set | Unit price excluding tax/USD | Amount/USD |

88mm synthetic cube | 66150 | 56.80 | 3757063.11 |

88mm solid cube | 4500 | 27.18 | 122330.10 |

88mm preheating cube | 350 | 42.48 | 14867.26 |

Total: | 3894260.47 | ||

3.2.COI of equipment

According to the analysis of 50 sets QMYG850 presses, the configuration is according to the standard configuration, the hydraulic system is according to the super-high pressure pump, the motor is calculated according to the service motor . The equipment investment mainly includes the host machine, electronic hydraulic system, Big block,small block,steel ring, anvil and other parts of the price.

No. | Name | Model | Qty./set | Unit price(ten thousand USD) | Subtotal(ten thousand USD) |

1 | Host machine | QMYG850 | 1 | 145 | 145 |

2 | Electronic hydraulic system | QMYG850 | 1 | 27.58 | 27.58 |

3 | Big block,small block,steel ring | QMYG850 | 6 | 1.5 | 9 |

4 | Anvil | 185x64 | 6 | 1.95 | 11.7 |

5 | Total(ten thousand USD) | 193.28 | |||

a.If the equipment uses a power-off protection UPS system, each system can connect three devices, and the cost should to be calculated separately.

b.If the equipment circulation cooling water system adopts the intelligent temperature control system, the cost of each equipment should to be calculated separately.

c. If the hydraulic system is overpressured, when booster is used for the overpressured system, the cost of each equipment hydraulic electronic control system should be calculated separately.